Medical Device Leak Testing

Medical device manufacturers also face regulatory hurdles. Namely, the U.S. Food and Drug Administration’s Title 21 CFR Part 11, and European Medicine Agency’s Annex 11, which regulates the transfer and protection of electronic records and applying electronic signatures. Our team of experts understand these complex regulations including instrument calibration, process validation, data collection & storage and how they relate to Industry 4.0 methodology.

- Cardiovascular devices and balloons

- Respiratory devices

- Catheters

- Syringes

- IV sets

- Blood bags

- Microfluidic Chips and reagent cartridges

- Implantable devices like pacemakers or pumps

Leak Testing Methods

There are several methods incorporated for medical device leak testing, each with its own advantages and limitations. The choice of method depends on factors such as the type of device being tested, its intended use, and regulatory requirements. Some commonly used leak testing methods include:

Visual Inspection / Water Immersion Test

This method involves immersing the medical device in water and applying pressure to try to identify any leaks. Any leaks or water ingress are detected by visible bubbles during pressurization. Water immersion is the least expensive method. However, this method is time consuming, highly subjective, creates safety concerns and (due to moisture) not suitable for many types of medical devices or manufacturing environments.

Pressure or Vacuum Decay Test

Pressure or vacuum decay is used to detect leaks in the 1-1000 sccm leak rate range. For pressure decay, a specific pressure is applied to the test component, after stabilizing, the tester measures the decay rate to determine product acceptance. For vacuum testing, a vacuum is created inside the test component and then monitored for any increase in pressure over time. If there is an increase in pressure, it indicates the presence of a leak.During initial setup, the decay characteristics of a “Master” non-leaking device with and without a known leak rate are memorized. Production devices are then referenced to these characteristics to verify the product passes the leak criteria.

Decay testing is simple & inexpensive with good resolution. Large leaks are easy to detect. The smaller the pressure loss being detected, the slower the test. Decay testing is also volume dependent. If the test part internal volume varies excessively (part to part) the test results will be variable as well.

Mass Flow Test

Mass flow leak testing is another commonly used method for detecting leaks in the 1 sccm to 200 SLPM leak rate range. Like Pressure Decay, with a Mass Flow the part is pressurized and allowed to stabilize. Once stabile, the leak tester measures the amount of “replacement” air volume required to maintain the setpoint pressure in the test circuit. Any replacement air required to maintain the setpoint is considered leakage and based on the leak limits applied, the medical device is passed or rejected.Mass flow testing is simple & inexpensive with excellent resolution. It is the preferred test method for parts that stretch when pressurized or vary in internal volume or have large dead volumes. Mass flow has also been proven to be less affected by part temperature variation when tested, resulting in less environmental drift.

Tracer Gas Test

Tracer gas testing using helium or hydrogen are the most expensive methods and typically not considered due to its excessive cost, environmental concerns and plant gas saturation should there be a gross leak. The method involves introducing a tracer gas into the test component, then using specialized equipment to detect leakage of the gas. The most used tracer gas for this purpose is helium due to its low concentration in the atmosphere and its ability to penetrate small leaks. A 95/5 Nitrogen/Hydrogen mix is also being used with fair results. Tracer gas testing can provide highly accurate results but requires expertise and is not suitable for most production environments. Significant ancillary equipment will also be required to capture any reusable helium.In addition to the testing methods mentioned above, there are also international standards and guidelines that provide recommendations for medical device leak testing.

UltraFlow V3

The ULTRAFLOW V3 leak tester is specifically designed to test large internal volume parts and is configured to test with either pressure decay or mass flow. Occlusion testing is available as well. The UltraFlow utilizes our patented pneumatic design which allows the instrument to test at a faster rate, while eliminating the “false rejects” commonly associated with this type of product.

UltraFlow V3-RT

The ULTRAFLOW V3-RT (Remote Touchscreen) is perfect for smaller workstations with limited space. With this configuration, the HMI can be mounted in a user-friendly location for programming and visual pass/fail status while the instrumentation enclosure can be tucked in a convenient location.Guardian

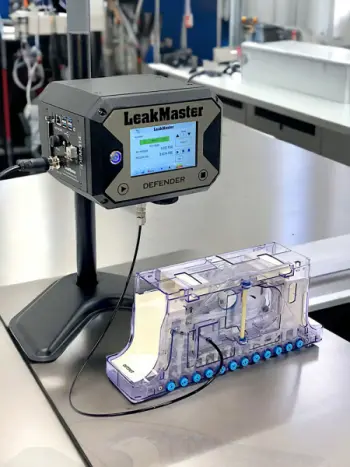

Defender

The DEFENDER tester is considered the best value of any pressure or vacuum decay leak tester on the market. Compact yet powerful, while providing excellent value and return on investment describe the Defender. It’s built for production usage and with Ethernet IP onboard, ready for seamless integration with Allen Bradley devices.Why Should You Leak Test Medical Devices?

Safety

Properly functioning medical devices are crucial for the safety of the world’s medical systems. Leaks can compromise performance, leading to accidents and potential litigation. By leak testing, companies help address this leading in-field safety issue.

Durability

By identifying and fixing leaks in their medical devices, manufacturers ensure the durability and longevity to the patient and practitioner.Regulatory compliance