AIR LEAK DETECTION EQUIPMENT

- Pressure Decay

- Vacuum Decay

- Mass Flow

- Differential Pressure

- Occlusion

- Metered volume (IP67)

- Volumetric Fill

Features are one thing, performance is another. In addition to designing our Air Leak Detection Equipment to pressurize or pull vacuum as fast as possible, all LeakMaster instruments utilize our lightning-fast 64 bit processor and 24 bit sensors for outstanding resolution over a wide pressure and leak range and utilize the largest porting available per tester footprint. This powerful combination of hardware and software provides outstanding repeatability and significantly reduces overall cycle time compared to other air leak detectors, resulting in excellent long-term value and return on investment.

LeakMaster air leak testers are easy and straightforward to set up and operate, utilizing a common user interface across all leak test instruments to build confidence, and eliminate confusion.

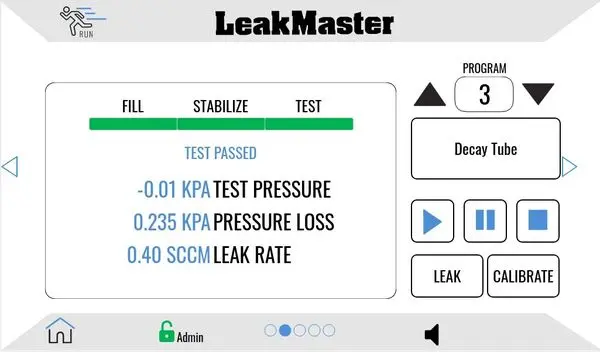

A typical air leak test sequence consists of 3 main steps, Fill, Stabilize & Test.

- Fill - During the Fill step, the part being tested is pressurized or evacuated to a specified level.

- Stabilize - During the Stabilize step the part is allowed to stretch/expand or contract (based on the test applied) and cool until stable.

- Test - During the Test step the pressure, vacuum or flow level is monitored, and the product is either a Pass or Fail at the end of the test step based on pre-set Leak or Flow limits.

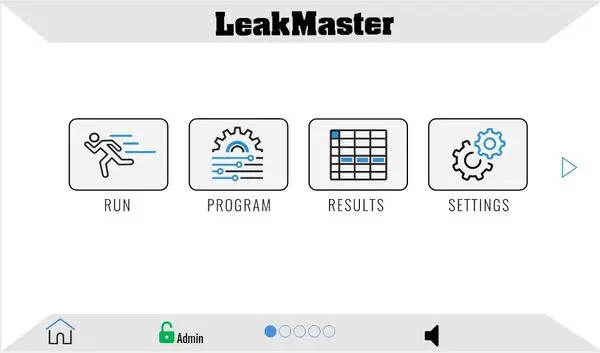

LeakMaster utilizes a simplistic, intuitive design on the interface of our leak test equipment with 4 main icons: Run, Program, Results, and Settings.

The Run screen displays the current phase of the test in process, including the real-time test pressure, pressure loss and calculated leak rate at the end of the Test. From this screen you can start, stop or pause a test, introduce a calibrated leak orifice into the circuit, or set up & calibrate a new leak test program.

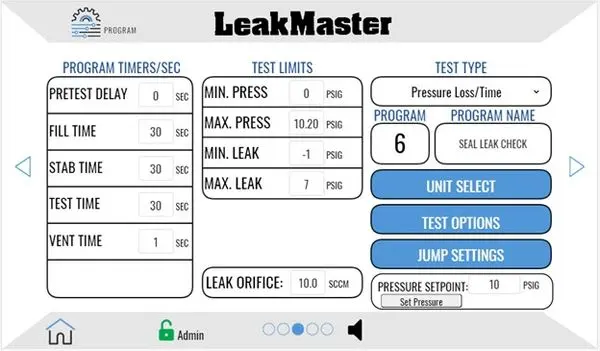

The Program screen is used to set Program timers, Pressure & Test limits and Calibration values. For ease of use, program timers are listed in order on the left side of the screen. The min-max pressure and leak limits are in the center. From this screen you also select the test type, unit of measure to be displayed and can name the programs as well. All programming screens are password protected.

The Results screen retains data from the last 3000 tests onboard and includes a graph of each test as well. The Results screen also has a built-in Auto-Save feature to save test data to a peripheral device such as a flash-drive. The data is saved as a CSV file (Excel) for ease of viewing. Data is highly detailed and can include a scanned barcode and operator sign-in.

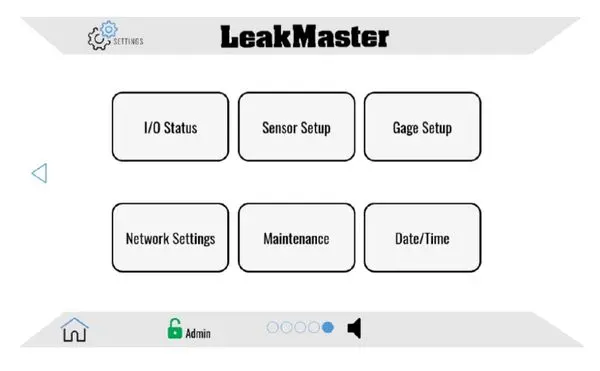

The Setting screen provides visual I/O status indication of the DB37 discrete I/O port and Ethernet IP™ network settings (2 ports). Maintenance and sensor setup screens are also located here. You can also save and export programs. There is also a page for performing a repeatability study, which makes running a CGK or GRR capability study effortless.

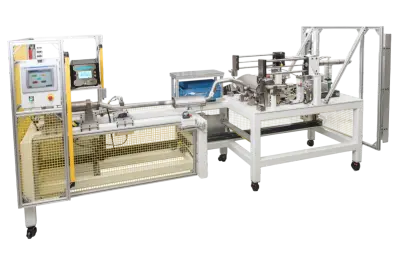

From complex automotive Seal Tooling or medical device Air Leak Detection Equipment, to Automated Leak Test Machines, you can count on LeakMaster to provide the robust leak testing solutions your company needs.

Contact Us

Feel free to utilize our Contact Us page today to connect to a knowledgeable team member about how we can support your facility with world-class leak detectors, unparalleled customer support and knowledge you can only receive from the experts at LeakMaster.

.png1758208500400265.666666666671200400265.66666666667.thumb.webp)